|

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Welcome

to the dissolved oxygen (D.O.) theory Page. Dissolved oxygen

from A to

Z Dissolved Oxygen:

The air we breathe contains about 20% oxygen. Fish and other aquatic organisms require oxygen as well. The term Dissolved Oxygen (DO or D.O.) refers to the amount of free oxygen dissolved in water which is readily available to respiring aquatic organisms. State water quality standards often express minimum concentrations of dissolved oxygen which must be maintained in order to support life as well as be of beneficial use. Levels of dissolved oxygen below 4-5 milligrams per liter affect fish health and levels below 2 milligrams per liter can be lethal to fish.

Additionally, biochemical oxygen demand (BOD) is commonly used with reference to effluent discharges and is a common, environmental procedure for determining the extent to which oxygen within a sample can support microbial life. The test for BOD is especially important in waste water treatment, food manufacturing, and filtration facilities where the concentration is crucial to the overall process and end products. High concentrations of DO predict that oxygen uptake by microorganisms is low along with the required break down of nutrient sources in the medium.

Basic

principles of Polagrography cell Liquid

and Air state of equilibrium is reached when the partial pressure of

oxygen, i.e. the part of the total pressure that is due to oxygen, is

equal in air and in liquid. The liquid is then saturated with oxygen.

Figure

1.1 Air and liquid oxygen equilibrium

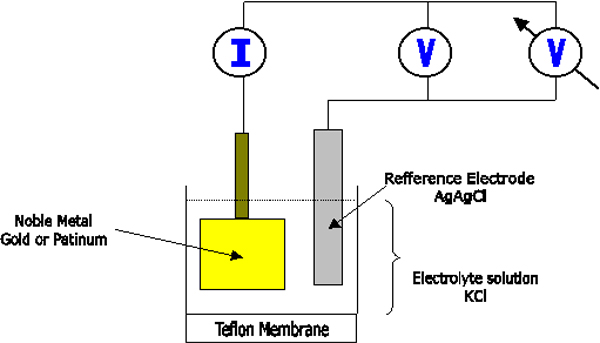

When

an electrode of noble metal such as platinum or gold is made 0.6 to 0.8 V

negative with respect to a suitable reference electrode such as AgAgCl or

an calomel electrode in a neutral KCI solution (see Figure 1.2), the

oxygen dissolved in the liquid is reduce at the surface of the noble

metal.

Figure

1.2 Polarographhy diagram

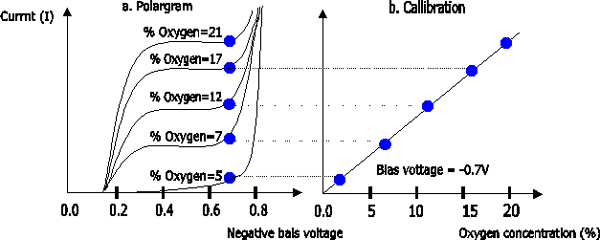

This

above phenomenon can be observed from a current to voltage diagram called a

polarogram of the electrode. As shown in Figure 1.3a, the negative voltage

applied to the noble metal electrode (called the cathode) is increased,

the current increases initially but soon it becomes saturated. In this

plateau region of the polarogram, the reaction of oxygen at the cathode is

so fast that the rate of reaction is limited by the diffusion of oxygen to

the cathode surface. When the negative bias voltage is further increased,

the current output of the electrode increases rapidly due to other

reactions, mainly, the reduction of water to hydrogen. If a fixed voltage

in the plateau region (for example, - 0.6V) is applied to the cathode, the

current output of the electrode can be linearly calibrated to the dissolved oxygen

(Figure 1.3b). It has to be noted that the current is

proportional not to the actual concentration but to the activity or

equivalent partial pressure of dissolved oxygen, which is often referred

to as oxygen tension. A fixed voltage between -0.6 and -0.8 V is usually

selected as the polarization voltage when using Ag/AgCl as the reference

electrode or any other EID's dissolved oxygen electrodes. Additionally

for physical and chemical correctness, partial pressure in a liquid

actually refers to the fugacity. In the pressure range relevant to the

measurements at hand, it is acceptable to equate the two values and this

allows us to restrict the following considerations to the partial

pressure. In dry, atmospheric air, the partial pressure of oxygen is

20.95% of the air pressure. This value is reduced over a water surface

because water vapor has its own vapor pressure and a corresponding partial

pressure.

Figure

1.3 (a) Current to voltage diagram at different oxygen tension; (b)

Calibration obtained at a fixed polarization voltage of –600 mV.

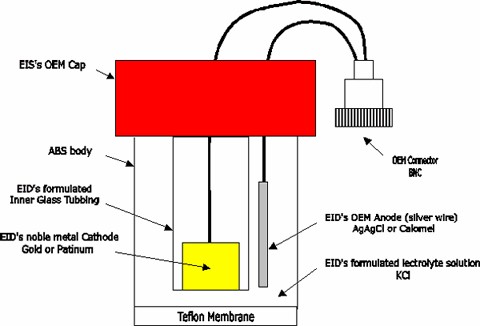

When

the cathode, the reference electrode, and the electrolyte are separated

from the measurement medium by a polymer membrane, which is permeable to

the dissolved gas but not to most of the ions and other species, and when

most of the mass transfer resistance is confined in the membrane, EID’s

electrode system can measure oxygen tension in various liquids. This is

the basic operating principle of the membrane covered polarographic

Dissolve oxygen probe (Figure 1.4).

The

basic principle underlying the electrochemical determination of oxygen

concentration is the use of membrane covered electrochemical sensors. The

main components of the sensors are the oxygen permeable membrane, the

working electrode, the electrolyte solution and a

possible reference electrode. A voltage is applied between the gold

(platinum or silver) cathode and the anode that consists of either lead or

silver (AgAgCl), and causes

the oxygen to react electrochemically. The higher the oxygen concentration

the higher the resulting electric current. The current in the sensor is

measured and, after calibration, converted into the concentration of dissolved oxygen.

If the anode is made of silver, the meter applies the required voltage (polarographic sensor). If it is made of lead, the sensor is self-polarizing, i.e. the voltage is generated in the sensor by the electrodes themselves, comparable to the process in a battery (galvanic sensor). The meter merely evaluates the current.

Figure

1.4 Basic Polarographhy electrode

EID’s

polaragraphoc dissolved oxygen electrode picture:

EID’s ELECTRODER - ABS body Dissolved Oxygen Sensor (ADO) EID’s dissolved oxygen, Probe, polaragraphic, ABS body, 12mm * 120mm, with 10K Negative Temperature Compensation Figure

1.5 Basic Polarographhy-electrode

For

our polarographic electrodes, the reaction proceeds as follows:

H202

+ 2e- -> 20H-

The

reaction tends to produce alkalinity in the medium together with a small

amount of hydrogen peroxide.

Two

principal pathways were proposed for the reduction of oxygen at the noble

metal surface. One is a 4-electron pathway where the oxygen in the bulk

diffuses to the surface of the cathode and is converted to H2O

via H2O2 (path a in Fig. 1.6). The

other is a 2-electron pathway where the intermediate H2O2 diffuses directly out of the

cathode surface into the bulk liquid (path b in Figure 1.6). The oxygen

reduction path may change depending on the surface condition of the noble

metal. This is probably the cause for time-dependent current drift of

polarographic sensors. Since the hydroxyl ions are constantly being

substituted for chloride ions as the reaction starts, KCI or NaCl has to

be used as the electrolyte. When the electrolyte is depleted of Cl-,

it has to be replenished.

2e- à (a) à

O2 à

O2 à

H2O2

Diffusion

à (b) à H2O2 Figure 1.6 alternative pathway of oxygen reduction at cathode surface

Calibration

must be carried out for dissolved oxygen measurements on a regular base.

This is because the measuring process consumes the electrolyte solution in

the sensor head, as shown by the electrode reactions presented above. The

ions of the electrolyte solution bind the released metal ions, thereby

changing the composition of the solution. The recommended calibration

period depends on the oxygen sensor used and ranges from one week for

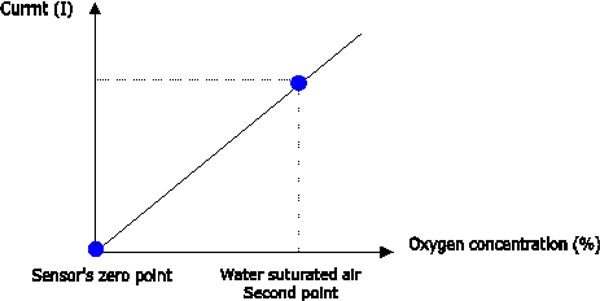

pocket instruments to 1-2 months. Each

linear calibration function is defined by at least two points. For dissolved oxygen

measurements with EID meter and/or logger, one of the

points on the line is the zero point of the sensor. At the zero point, the

sensor signal obtained in the absence of oxygen lies below the resolution

of the sensor. This point is called the zero-current point of the sensor.

The second point of the calibration line can be set as required. Its

position is based on the fact that, in a state of equilibrium, the partial

pressure of oxygen in liquid and air is equal.

Figure

1.4b Two-point calibration

The rate at which oxygen enters a dissolved oxygen probe is a function of:

As described above calibration routines for dissolved oxygen probes use a two point linear calibration where one point is at zero mg/L oxygen and the second point is at saturation or equilibrium with the atmosphere, C* . The zero measurement is not zero volts due to the conductivity of the electrolyte between the electrodes as well as any errors in the analog signal conditioning circuit. For the circuit and probe system used in the Environmental lab the zero measurement is approximately 1 mV (where approximately 200 mV corresponds to saturation levels of oxygen) and hence the zero measurement is not significant. Thus a single point calibration is used.

C* is a function of the atmospheric pressure and temperature. The functional relationship with temperature is implemented using a lookup table (based on equilibrium at atmospheric pressure) with interpolation. The effect of atmospheric pressure is implemented as shown (Equation 1 below).

P C* =------- f (T) Patm

The permeability of the membrane increases about 5% per C degree. I chose to use 25 C as the reference temperature and thus Kmembrane(Tref) has a value of 1. The following (equation 2) creates a coefficient that describes this variation.

Kmembrane(T)=Kmembrane(Tref)e0.05(T-Tref)

The slope of the linear fit (k) can be calculated after the voltage corresponding to saturation oxygen is measured (Equation 3 below).

C*cal Kmembrane C =------------------ V*cal

The slope coefficient is placed in the polynomial array.

The equation for the dissolved oxygen concentration illustrates that the predicted concentration is a function of sample temperature because Kmembrane varies with temperature. The coefficient, k, should be independent of temperature but will vary as a membrane fouls (Equation 4 below)

KV C=----------- Kmembrane

Pressure

The constituents of air have been well defined, and it is known that air contains 20.946% oxygen. Since the total pressure in the air is the sum of all of the partial pressures (Dalton’s Law), an atmospheric pressure of 760 millimeters Mercury (mmHg) in dry air will contain a partial pressure of oxygen (pO2) of approximately 159 mmHg (760 mmHg * 0.20946). Changes in atmospheric pressure will cause a directly proportional change in the partial pressure of oxygen in the air. Atmospheric pressures will vary depending upon altitude and local weather conditions. Some average pressures for varying altitudes are listed in Table 1 bellow.

The relationship between oxygen partial pressure and total atmospheric pressure should be understood and incorporated into the air calibration in order to minimize calibration error, which could be as high as 5-10% dependent upon altitude and local weather conditions. Most dissolved oxygen meters that have any sort of advanced air calibration (such as temperature compensation, which will be discussed in a later section) will be based upon an atmospheric pressure of 760 mmHg. Most tables of oxygen solubility are referenced to this value. Because of the change in oxygen partial pressure with changes in atmospheric pressure, a correction must be made when the pressure varies from this value. A simple means of incorporating pressure changes is listed in the “correction factor” shown in Table 1 bellow. The value listed is a rough multiplier, which can be used once the initial oxygen concentration is determined based upon temperature and relative humidity. A more accurate calculation for incorporating pressure will be discussed after relative humidity and temperature effects are investigated.

Some EID’s dissolved oxygen meters contain a pressure sensing device which provides compensation for pressure effects when an air calibration is performed. If you use our electrode on not-EID-meter, since most meters do not have this, it is usually necessary to note the average pressure in the local vicinity of the probe, which will be mostly altitude-based, and adjust the calibration using the simple correction factor or the more complex calculation performed later. A mercury barometer located in the immediate vicinity of the meter will give a relatively accurate measurement of the local atmospheric pressure if an older meter with no pressure sensor is used.

Table 1: Oxygen Value Corrected for Pressure (25 °C)

Relative Humidity and temperature effect and Temperature compensation

If desired the Eid's probes can be coupled with a temperature thermistor (10K Ohms) to achieve temperature compensation since Kmembrane varies with temperature.

The discussion of pressure effects were based upon atmospheric pressure with dry air (no moisture content). Whenever air contains a certain amount of moisture, the atmospheric pressure contains another source of partial pressure -- water vapor. If a comparison of the oxygen partial pressure in air with 100% relative humidity and air with 0% relative humidity is done while both are at the same atmospheric pressure, the air with 100% relative humidity will have a lower oxygen partial pressure due to the presence of the water vapor pressure (pH2O). Water vapor pressure in air varies with temperature, and is well defined. The effect of temperature on oxygen partial pressure in moist air is such that higher temperatures yield lower oxygen partial pressure, while lower temperatures yield higher pressures. Note that the effects of relative humidity and temperature can cause errors when air calibration is performed in dry air, since most of the current tables and meter temperature compensations are based on air containing 100% relative humidity. Table 2 bellow shows both the oxygen concentration, which is linear with the partial pressure of oxygen, that would be present at 100% relative humidity and 0% relative humidity. The values only differ by a few percent in ambient air conditions, and thus is generally ignored. Most dissolved oxygen meters have temperature compensation for air at 100% relative humidity, and no manual correction is necessary. However, many older meters do not have temperature compensation included, and therefore this calculation must be done manually. If temperature is not compensated for in the calibration, the error can be as much as 20 to 30 % for every 10 degrees difference from 25 °C, and therefore temperature compensation is standard on most dissolved oxygen meters today. Since the effects of relative humidity is minimal at all but the highest temperatures, no current dissolved oxygen meters incorporate any kind of relative humidity sensing device. In order to ensure an accurate temperature and current reading, the probe must be exposed to the air for enough time to allow thermal equilibrium to occur. There are often significant temperature differences between the process water and the ambient air. Larger temperature gradients between the two necessitate additional time for thermal equilibrium to take place. For instance, a 20 °C difference between ambient air and process water can cause a calibration delay of about 30 minutes in many probes for the probe to fully equilibrate to ambient temperature. Since most temperature gradients will not be this large, allowing approximately 15 minutes is usually a safe assumption. It is common for users to calibrate the unit before the dissolved oxygen meter is reading the stabilized temperature and current value, which can cause significant error since a difference of even 5 °C from actual can cause the reading be off by 5 to 10%. It is often useful to have a calibrated temperature sensor, accurate to 1 °C or better, at the calibration location to know when the probe temperature is reading the correct ambient air temperature. It is useful to have an equation which can be used to determine oxygen concentrations in air based upon temperature, relative humidity, and pressure. Since the full equation is quite lengthy and complex, two easier versions are presented to the user, along with Table 2 bellow, to determine the correct oxygen concentration in air. Equation 5 bellow should be used with air with 100% relative humidity, and Equation 6 should be used for air with 0% relative humidity.

Equation 5 (100% Relative Humidity): OS = (OS’) * (P - p) / (760 - p) where:

OS = Oxygen solubility at barometric pressure of interest OS’ = Oxygen in saturation at one atmosphere (760 mmHg) at a given temperature P = Barometric pressure of interest p = Vapor pressure of water at the temperature of interest Example 1:

The user wishes to calibrate a dissolved oxygen probe in air at an altitude of 3500 feet. The temperature is 30 °C, and the relative humidity is 100%. At an altitude of 3500 feet, the atmosphere pressure will usually be about 668 mmHg (Table 1 above). The sample temperature is 30 °C, and the relative humidity is 100%. From water vapor pressure tables, the water vapor pressure at 30 °C is 31.8 mmHg. The oxygen saturation level at 760 mmHg and 30 °C is 7.54 ppm (Table 2 bellow). Substituting these values in the above (equation 5) gives the following:

OS = (7.54) * (668 - 31.8) / (760 - 31.8) = 6.59 ppm

Example 2:

Assume the same conditions as in example 1, but with a relative humidity of 0%. In this case, the value used for the oxygen saturation level would be 7.87 (Table 2 bellow), not 7.54. The calculation will change since there will be no water vapor pressure. Equation 6 (0% Relative Humidity): OS = (OS’) * (P) / (760 mmHg) Substituting the above values into the equation yields the following:

OS = 7.87 * (668) / (760) = 6.92 ppm Note: that the multiplier of (668) / (760) is actually the simplified correction factor listed in Table 1 above for an altitude of 3500 feet (0.88). Table 3 bellow lists calibration values for varying temperatures pressures at relative humidity levels of 100%.

Table 2 above: Dissolved Oxygen Solubility vs. Temperature

Table

3 above: Oxygen concentration (ppm) for varying pressures (mmHg) and

Calibration

in air saturated with water vapor:

This

requirement is met over large water surfaces, such as lakes or the sludge

activation basin of a wastewater treatment plant. Note: EID’s offers special air calibration vessels for laboratory measurements.

Calibration

in air saturated water:

The

water is aerated until the partial pressure of the oxygen in the water is

the same as in the air. This method is accompanied by some inherent risks:

As

you can see from the above list, is clearly preferable to calibration in

air-saturated water.

Relative

slope limitation, to evaluate the sensor function despite it, there are

three characteristic measuring points in addition to a visual test. In

the visual test, the gold cathode is examined visually. If it has lost its

gold or platinum color and is coated with lead or silver, the sensor will

yield values that are too high and will generally no longer be

zero-current-free. This can be corrected by regenerating the oxygen sensor

as described in the operating manual. The gold cathode may only be

polished with a moist special abrasive film using a circular motion with

little pressure. It is imperative that only this special film be used

since a scratched and unpolished electrode surface can harm the sensor and

impair its accuracy. Attention:

Anodes of lead or silver cannot be polished at all. One

subjective, visual examination of the sensor can be supplemented by a more

comprehensive test, an evaluation at three specific measuring points: in

air saturated with water vapor (1), in air saturated water (2) and in

oxygen free water (3). 1.

Test in air saturated with water vapor: The

sensor should obtain a reading between 100 and 104% oxygen saturation in

water-saturated air. If the values lie above this range, the membrane was

probably wet during calibration; perhaps there is too much water in the

calibration vessel. A value above 100% saturation is due to the differing

viscosity of water and air as well as to the surface tension of water. To

put it simply, it is easier for oxygen molecules in the air to permeate

the membrane than for those in the water to dissolved oxygen so. In the measuring mode,

which is the mode in which the test takes place, calculations are based on

a liquid sample and this results in a saturation level over 100%. 2.

Test in air saturated water: After

calibration, the value in air-saturated water should lie between 97 and

102% saturation. The theoretical value is 100% but is difficult to

reproduce. This relatively large tolerance is due not to the sensor but to

the saturation procedure. This is also the reason why EID successfully

sought an alternative to the conventional calibration procedure in

air-saturated water. If the sensor dissolved oxygen not display a reading within this

tolerance range, it should be sent back to the manufacturer for tests. 3.

Test using zero solution: This

is to test the zero current point of the sensor. When the oxygen content

is 0 mg, the maximum reading of the sensor should not exceed the

resolution of the meter (1 digit). This test is carried out using sodium

sulfite solution. Sulfite reacts with the dissolved oxygen to form

sulfate, binding the oxygen dissolved in the water. Preparation

of the solution: Dissolve a teaspoon of sodium sulfite in

100 ml tap water. The solution will be oxygen free after it has stood

undisturbed for 15 minutes. It must remain undisturbed to prevent oxygen

in the surrounding air from re entering the solution. One minute after

submerging paleographic sensors (EID-E-ADO–A001,

EID-E-ADO-A002, etc.)

Into the solution, the meter should display a maximum reading of 2%; after

15 minutes, the maximum reading should be 0.4%. If not, the sensor is no

longer zero current free and must be cleaned or sent to the manufacturer

for tests. After the test, the sensor should be rinsed thoroughly with

distilled water to remove any remaining traces of sodium sulfite solution.

Galvanic

sensors with lead counter may be submersed for no more than 3 minutes.

Subsequently, they must also be rinsed thoroughly with distilled water.

Cleaning of the sensors is extremely important to prevent toxification and

lasting damage.

Measurement

and analytical quality assurance:

Measurement

of the oxygen concentration is now quite easy to carry out. The sensor is

submersed in the liquid to be investigated and the measured value is read

from the display. In principle, this is all there is to it, but

nevertheless a few important points should be observed and among those is

the proper maintenance of the sensors.

The

component of the sensor that is sensitive to contamination is the

membrane. Contamination results in lower readings when measuring or lesser

slopes when calibrating because a portion of the membrane surface is not

available for the diffusion of oxygen. The attempt to compensate for the

contamination by adjusting the instrument does not agree with the water

principle. It is preferable to clean the membrane. Acetic or citric acid

with a concentration of 5--10% (percent in weight!) is used for calcium

and iron oxide deposits and warm (<50C) household detergent is used for

fats and oils. Avoid

strong mechanical treatment of the membrane during all cleaning activities

because its thickness is on the order of m and it is easily destroyed. It

is best to use a soft paper towel. Dissolved oxygen not clean the sensor in an

ultrasound bath as this may cause the coating of the anodes to peel off.

Regeneration

of the sensor becomes necessary when the function responds or when the

slope (S) < 0.6 has decreased markedly when calibrating. Basically,

regeneration is required when the electrolyte solution is depleted, when

the gold cathode has become coated with lead or silver, when the reference

electrode is to xified or when the membrane is damaged or contaminated. It

consists of exchanging the electrolyte solution, cleaning the electrodes

and exchanging the membrane head. It

is important to follow the operating manual exactly! Mistakes are then

easily avoided. The

following points should be emphasized:

Please

note: The spacing lattice is clearly visible when the membrane head

is held up against the light. The

result of an oxygen measurement can be documented in several ways:

Polarization

periods (startup periods) prior to measurement:

If

the sensor was disconnected from the meter, an appropriate polarization

period must elapse after the polarographic sensors are reconnected

(gold-silver electrode system) before the start of measurements. Please be

advised that this does not apply to galvanic sensors (gold-lead electrode

system) because they are self polarizing and can be used immediately.

The

approach flow to the sensor membrane must be continuous for oxygen

measurements to be correct. The diffusion of the oxygen molecules in the

sensor head creates an oxygen poor zone that simulates a reduced

concentration of oxygen. The concentration at the membrane must always be

the equal to the concentration in the remainder of the sample. This

condition can be met by stirring the sample or moving the sensor in the

sample. EID

offers special stirring attachments that rotate like little turbine blades

and continuously supply the membrane with fresh sample. They are driven by

an alternating electromagnetic field that is generated by the base of the

stirrer.

The

major advantage of this unit is the size of the attachment. It has the

same diameter as the sensor and is mounted on the sensor head. This

simplifies measuring in sample bottles such as bottles for BOD

measurements. The

EID-E-ADO–A001 sensor is specially designed for BOD measurements. The

sensor shaft contains a propeller similar to a marine screw propeller to

maintain a continuous approach flow at the membrane. The stirring effect

is sufficiently large to homogenize the sample in addition to generating

the approach flow. If

agitators or magnetic stirrers are used, the possible formation of eddies

must be taken into account. The oxygen sensor may not be positioned in the

eddy because air at the sensor head Approach

flow membrane may falsify readings. This can be prevented by lowering the

stirring frequency or positioning the sensor away from the eddy. When

the sensor is installed in pipelines, the sample flows past the sensor

head, providing a sufficient approach flow. EID offers stationary

measuring systems with special installation assemblies for pipes. Alternatively,

the sensor itself can be moved in the medium being investigated, e.g. by

stirring the sensor in a beaker or by swinging it back and forth in a

lake. For measurements at great depths, depth armatures for water depths

up to 100m are available. It

is important that stirring does not falsify the measured values. This is

likely to happen when the investigated sample is supersaturated or under

saturated with oxygen and oxygen can be expelled from or stirred into the

sample. Super

saturation with oxygen, for example, can be observed in the summer in

stagnant waters when luxuriating algae produce oxygen by photosynthesis.

An example of under saturation with oxygen is the BOD determination in

which bacteria lower the oxygen concentration in bottles through

respiration. For this reason, the volume of the sample is important. A

measurement taken in a lake or an activation basin is uncritical because

of the enormous quantity of the sample. In an open beaker, however,

stirring can easily alter the oxygen concentration.

The

temperature dependent Bunsen absorption coefficient changes when

substances are dissolved in the water. This effect is accounted for by

entering the salinity. The salinity can be determined using a conductivity

meter and corresponds to the salt content of seawater in g/kg. The

standard recommends the use of this function for other waters since the

deviation is minimal (<2%).

Influence

of interfering gases:

The

membrane is also permeable to gases other than oxygen. Nitrogen does not

react and is, therefore, irrelevant. The high pH value of the electrolyte

solution protects the measurement from the interfering influence of

ammonia. Carbon dioxide, on the other hand, is problematic. The buffering

capability of the electrolyte solution is sufficient for short-term

exposure; during long-term exposure, however, carbon dioxide shifts the pH

value into the acidic range and leads to increased values. Polarographic

sensors can better regenerate the buffer capability than galvanic sensors

because they generate an excessive number of hydroxide ions during the

electrode reactions. The buffer capacity of the electrolyte solution in

the sensor is insufficient for samples with a high carbon dioxide content

(e.g. beer, sparkling wine or soft drinks). The pH shifts into the acidic

range and the meter shows higher than normal readings. Hydrogen sulfide

presents the greatest danger for oxygen sensors because the sulfide-ions

generated by the neutralization reaction toxify the counter electrode. The

sensors can withstand small amounts, but continuous exposure markedly

shortens their lifetime. Hydrogen

sulfide has the smell of rotten eggs and is easily perceptible at very

small concentrations, eliminating the need for complex measurements.

In order to determine the concentration of dissolved oxygen in non-aqueous liquids, the appropriate solubility function must be known. High performance dissolved oxygen meters and logger from EID have stored software programs that make this type of determination feasible. If the solubility function is known, oxygen measurements can be carried out similarly to measurements in water.

Checking the oxygen meter and or logger:

The METER-D0 (meter) or PROBER-DO (data logger) are checked using simulators. The simulators are connected to the instrument in place of the sensor. They generate defined current signals that the instrument must display correctly. If the readings lie outside the tolerance indicated by the certificate, the instrument must be sent to the manufacturer for servicing.

A.

Foods and Beverages C.

Fish Farming - Aquaculture F. Sea cages

K. Measuring biochemical oxygen demand

The BOD test requires a commitment of five (5) days from initial sample collection to the end of the analysis. During this time, samples are initially seeded with microorganisms and supplied with a carbon nutrient source of glucose-glutamic acid. The sample is then introduced to an environment suitable for bacterial growth at reproducible temperatures, nutrient sources and light within a 20C incubator such that oxygen will be consumed. Quality controls, standards and dilutions are also run for accuracy and precision. Determination of the dissolved oxygen within the samples can be determined through titration. The difference in initial DO readings (prior to incubation) and final DO readings (after a five (5) day incubation period) predicts the BOD of the sample. A suitable detection limit as per environmental quality control is 1 mg/l. BOD calculations

Steps to calculate Biochemical Oxygen Demand (BOD). They and are based on the addition of a nutrient source (carbon - glucose - glutamic acid) and no nutrient source.

1. The BOD of the blanks (no nutrient source) = DOFinal - DOInitial

2. The BOD of the nutrient added samples = (DOFinal - DOInitial) time dilution factor per 300ml

* 300 ml is based on the volume contained in BOD bottles

The BOD of the sample and standards are calculated by subtracting the final DO from the initial DO and multiplying this factor by the dilution factor. The final value is determined by subtracting out the BOD for the blank from the BOD that has been nutrient enriched.

Preparations:

All

practical experiments should be carried out in a suitable laboratory to

guarantee working safety. This is a general recommendation. In the field

of oxygen measurement, the cleaning solutions and the electrolyte

solutions may contain caustic substances. A possible danger therefore

exists when regenerating the sensor. Safety

instructions. General rules of conduct when handling chemical substances When

working at a work place at which chemicals are handled, the following

rules must be observed: 1.

Follow the instructions on the chemical bottles 2.

Always wear protective garments (goggles, gloves...) 3.

Never point open containers towards other persons 4.

Do not eat, drink or smoke 5.

Ensure the satisfactory disposal of chemicals 6.

Carefully remove or clean up any spilled chemicals 7.

Contact specialist personnel if any serious problems arise We

provide these short instructions in the hope that they lead to successful

and safe practical research and studies. Safety

data sheets are available for the cleaning and electrolyte solutions. The

user must have one of these data sheets. Because they are fairly

comprehensive, they cannot be included in every delivery. The manufacturer

will, however, provide them on request. The

following equipment and facilities must be present when you are measuring

dissolved oxygen:

|