|

Industrial Multi Configuration DC motor Variable speed control module is an Original Manufacturing Engineering (OEM) industrial and commercial rated high performance, high efficiency Direct current (DC) speed control.

The PIVOT P2 drive is a reliable and cost-effective solution for controlling your permanent magnet or shunt-wound DC motors in variable-speed applications. It uses SCR's to provide full-wave rectification of the AC line input. This dual voltage drive operates using 110VAC/115VAC/120VAC, 50/60Hz, to operate 90VDC SCR brush-type Fractional HP (FHP) and HP motors from 1/8 to 2 HP.

The DC Variable Speed Motor Control is a feature rich electronic interface board module designed to control 90V DC permanent magnet (PM) or Shunt-Wound (SHWD) motor locally via potentiometer and/or switch. The output average voltage is a linear function of the potentiometer rotation. If used properly, it will eliminate the need for expensive boards and instruments, which would otherwise be required to carry out the same control tasks.

Depending on model, the control can drive a 90V DC PM motor at verity of Horse Power (HP), while powered by standard 120VAC/60HZ. Therefore, it can be powered by US standard power source. It provides smooth control operation with high efficiency in a compact form.

The EID-PIVOT-P2 driver used in applications require constant torque throughout the application with good speed regulation such as conveyors, extruders, winders, printing presses, food process equipment and metering pumps controlled by 90VDC Permanent Magnet (PM) Horse Power Motor.

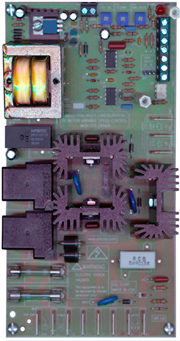

The board offers the features needed for professional high current DC motor control. The board also include built-in on board protection fuses, and transient and surge suppression.

The PIVOT P2 drive constructed with solid‑state, full wave design with Integrated circuitry using state‑of‑the‑art electronics ‑ ensures a fast, accurate response. Both AC input lines fused ‑ maximizes drive protection. Additionally on board start/stop control relays ‑ prevents restart of drive after power interruption. Furthermore controlled acceleration and deceleration of 0 to 10 seconds ‑ provides both, soft motor starting and stopping.

Mounting is easy via four 0.156" mounting holes using 6-32 screws and wire (optional) via convenient conventional industrial standards 90 degrees (.187) high current Quick-Fit terminals.

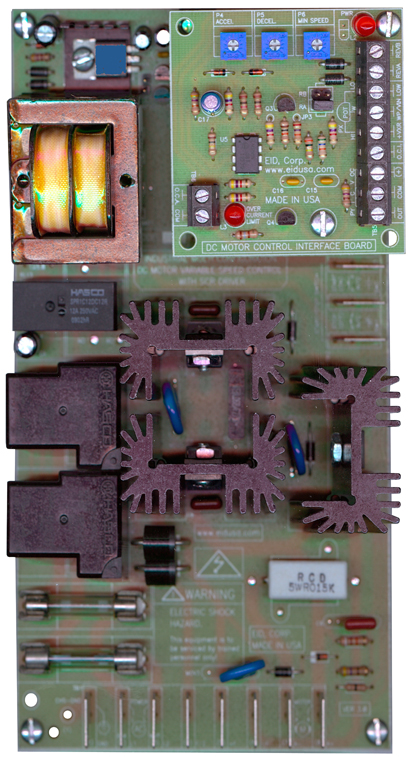

Shown above EID-PIVOT-P2 (with daughter-board), Industrial PM DC Variable speed Motor Control Basic Board

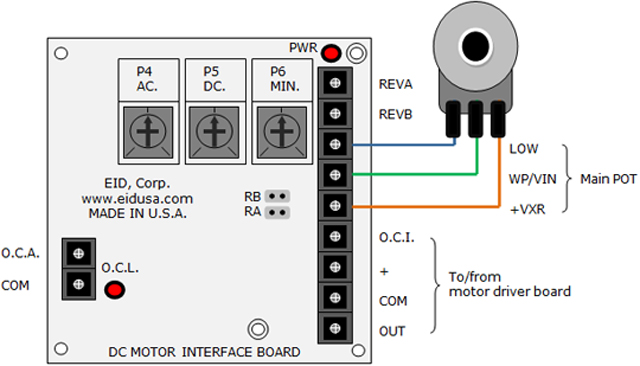

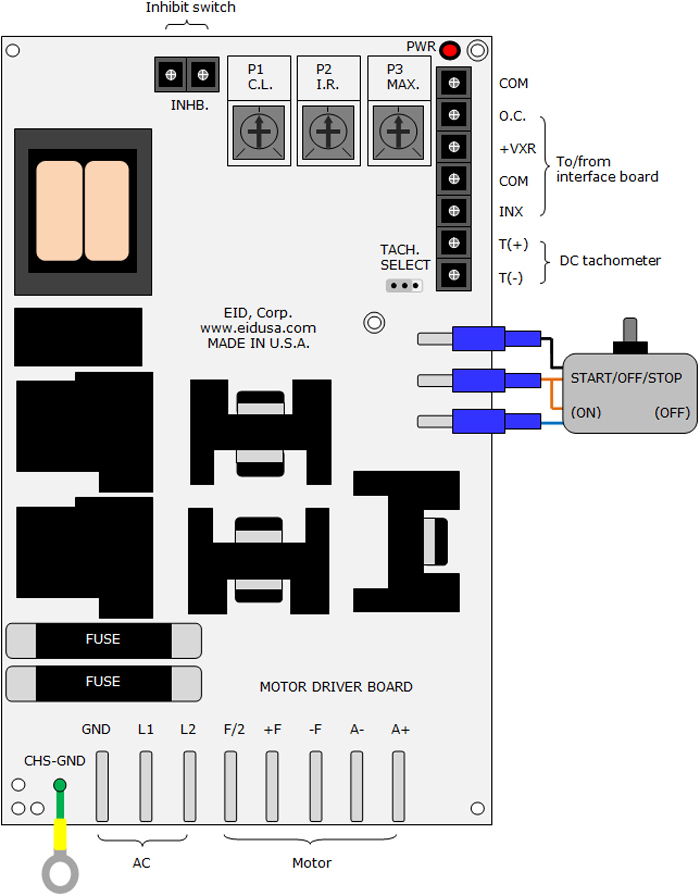

Shown above PIVOT-P2 (interface "daughter-board" top and main driver bottom) basic connections illustration

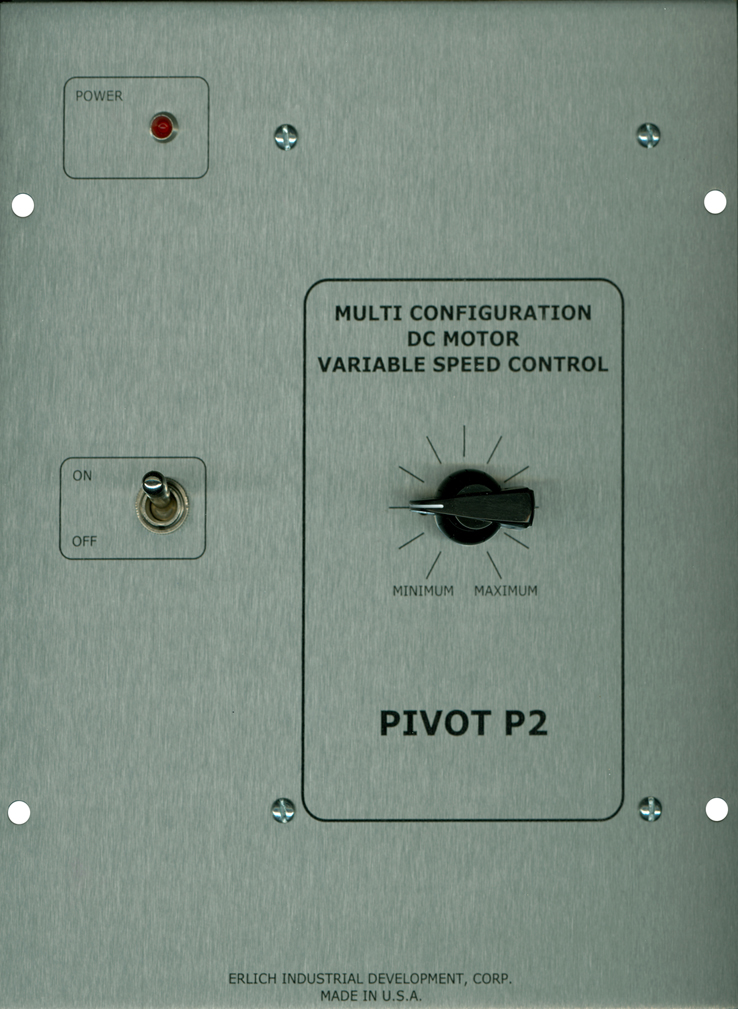

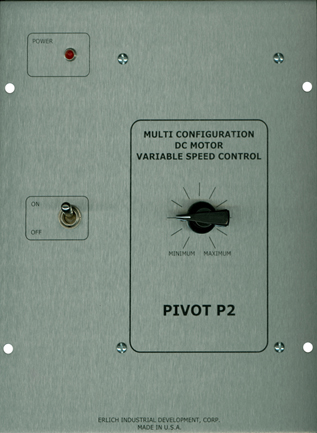

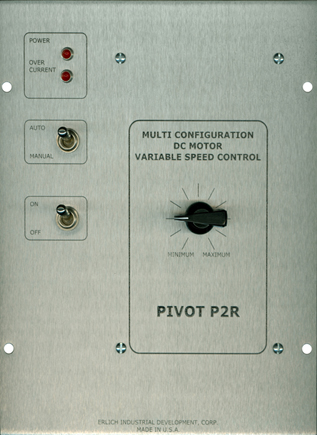

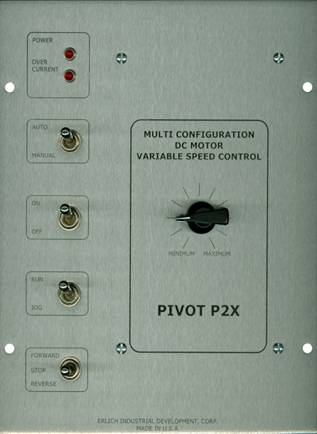

Front Panel

Shown above EID-PIVOT-P2, Industrial PM DC Variable speed Motor Control panel module with ON/OFF switch, speed adjustment POT/Knob and Power indicators

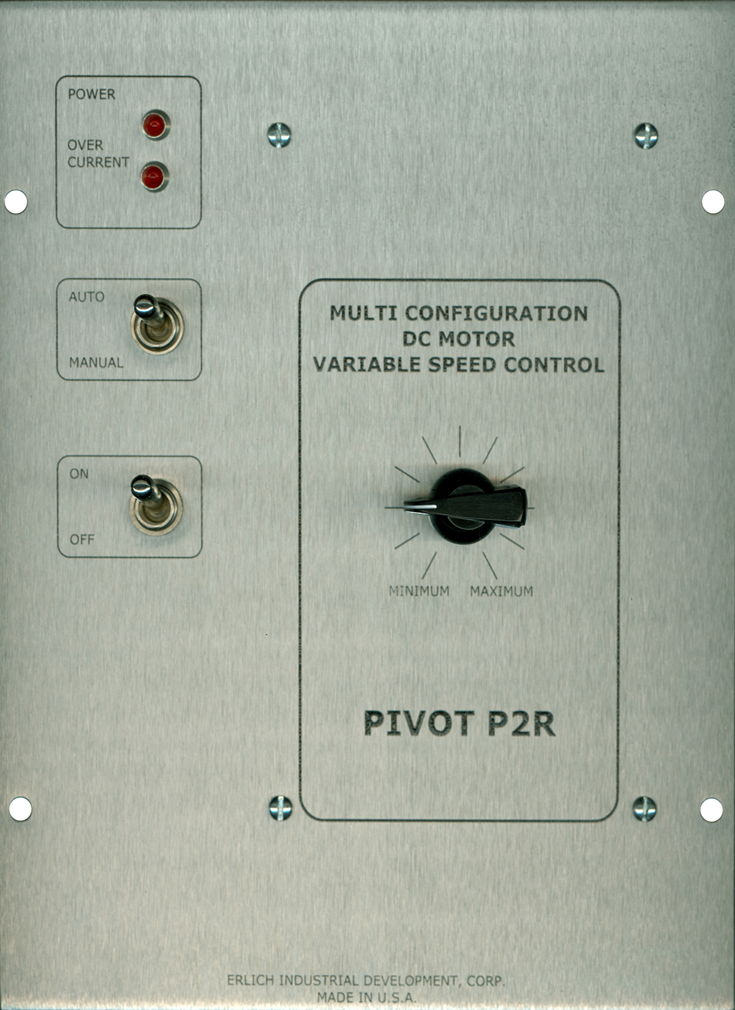

Shown above EID-PIVOT-P2R, Industrial PM DC Variable speed Motor Control panel module with ON/OFF and Auto/Manual switches, speed adjustment POT/Knob and Power/Over-Current indicators

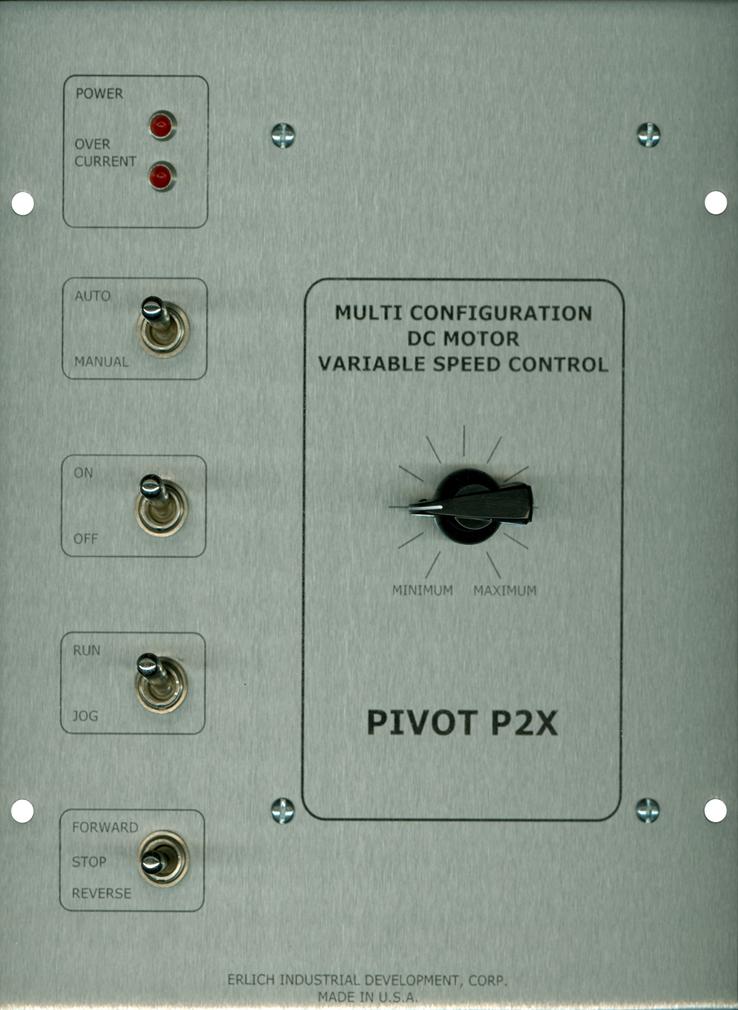

Shown above EID-PIVOT-P2X, Industrial PM DC Variable speed Motor Control panel module with ON/OFF, Auto/Manual, Run/Jog and Forward/Stop/Reverse switches, speed adjustment POT/Knob and Power/Over-Current indicators

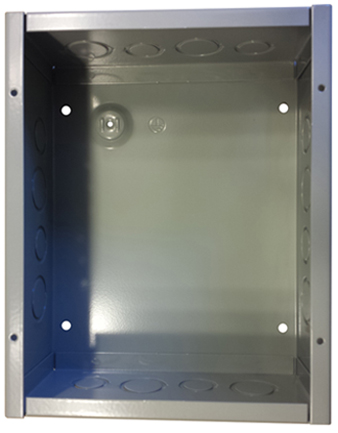

Enclosure

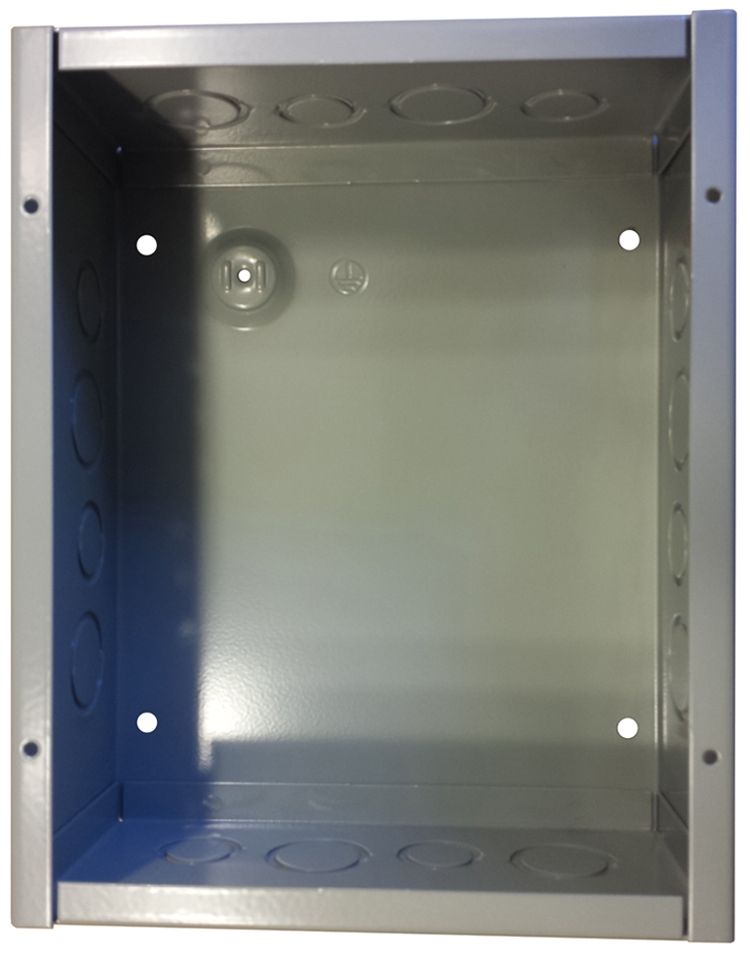

Shown above EID-PIVOT-P2's basic general purpose indoor commercial use enclosure (NEMA-1) Enclosure P# EID-PIVOT-CSKO1084

PIVOT-P2 Industrial applications:

● General Industrial PM Brush Motor drive ● Machinery PM Brush Motor drive ● Packaging Equipment PM Brush Motor drive ● Material Handling PM Brush Motor drive ● Laboratory Equipment ● Office Machinery ● Machine Tool Equipment ● Process Control Instruments ● Automatic Door and Gate Operators ● A Variety of Pump Applications ● Food Processing Equipment ● Chemical Dispensing ● conveyors ● winders ● printing presses

Standard Features:

● Provides motor with smooth variable speed ● Maintains variable speed ● Adjustable maximum (MAX) speed, minimum (MIN) speed ● Adjustable current limit (C.L.), I.R. compensation (I.R.), acceleration (ACC.), and Deceleration (DECL.). ● Inhibit terminal permits optional start-stop without changing the main speed potentiometer position. ● High efficiency circuitry. ● On board protection fuses. ● Start/Stop delay function, model depended. ● On board Metal Oxide Varistor (MOV) Transient Protection ● Conveniently front mounted high current Quick-Fit terminals. ● Conveniently front mounted LED or Neon power on indicator. ● Conveniently front mounted LED or Over Current indicator. (model depended) ● Large front mounted auxiliary heat-sinks for heat distribution for 1/8 to 2 HP models.

Control Board Dimensions:

Board width, length, height: 4.275" * 7.275" * 2".

Controller Enclosure Dimensions (option):

Board width, length, height: 11" * 8" * 5" (include switch toggle and bottom mounted wire-glens).

Control Board Mouthing Dimensions:

Four (4) mounting holes (.156" Dia.) 3.975" * 3.775" on center.

Note: Use four (4) 6-32 screws and stand-offs to mount the board to the optional panel.

Caution: Do not mount controller where ambient temperature is outside the range of -10° C (15° F) to 45° (115° F). -20°C to +50°C (-4°F to 122°F).

Specifications:

Model and Part Number (P#) Selection:

Board only

Board with panel

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||